| ● Available ★Indude SOI Process | |||||

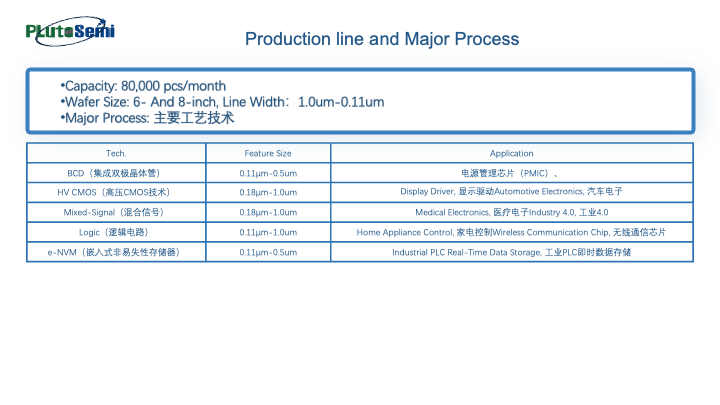

| Tech. | BCD | HV CMOS | Mixed-Signal | Logic | e-NVM |

| 0.13μm/0.11μm | ● | ● | ● | ||

| 0.18μm/0.153μm | ● | ● | ● | ● | ● |

| 0.25μm | ● | ● | |||

| 0.35μm | ● | ● | ● | ||

| 0.5μm | ● ★ | ● | ● | ● | ● |

| >0.5μm | ● | ● | ● | ||

| >1.0μm | ● | ● | ● | ||

| MEMS | Pressure sensor,Microphone sensor,Photoelectric MEMS and Thermopiles sensor are available. Accelerometer,Gas sensorand Micro-mirrorare under development. |

||||

| Special Device | APD/SPAD are underdevelopment. | ||||

| ★Advanced BCD Available ▲Advanced BCD Developing ●HV /UHV BCDAvailable ⊙Include SOI Process | |||||||

| 0.11μm | 0.153μm | 0.18μm | 0.25μm | 0.5μm | 0.8μm | 1.0μm | |

| 12V | ★ | ★ | ★ | ★ | |||

| 18V | ★ | ★ | ★ | ★ | |||

| 24V | ★ | ★ | ★ | ★ | |||

| 30V | ★ | ★ | ★ | ★ | |||

| 40V | ★ | ★ | ★ | ● | ● | ||

| 60V | ★ | ★ | |||||

| 80V | ★ | ||||||

| 120V | ★ | ●⊙ | |||||

| 200V | ▲ | ●⊙ | ● | ● | |||

| 600V | ●⊙ | ● | ● | ||||

| 700V | ● | ● | ● | ||||

| 1200V | ● | ||||||

| Region | Key Sectors | Our Solutions |

|---|---|---|

| North America | Quantum chips · AR/VR optics | 28nm SOI test vehicles · Metasurfaces |

| EU | Automotive MEMS · Medical implants | ASIL-D sensors · Biocompatible packaging |

| Japan/Korea | Display microdrivers · Power modules | μLED transfer · SiC trench etching |

| Southeast Asia | Advanced packaging · IoT sensors | Fan-out RDL · Ultra-low power RF SoC |