Analysis of semiconductor wafer development trends

一、Technology Evolution: Towards higher precision and integration

(一)The process continues to be scaled down

The semiconductor industry follows Moore's Law and is constantly striving for smaller process processes. From the early micro-scale to today's nano-scale, process scaling enables more transistors to be integrated into a chip, thereby improving chip performance and reducing power consumption. At present, the 5nm and 3nm processes have been mass-produced, and the 2nm process is also in full swing. For example, TSMC occupies a leading position in the global foundry market with its advanced process technology, and its 3nm process technology has been applied to chips from companies such as Apple, bringing more powerful performance to products.

(二)The rise of 3D integration technology

As process miniaturization approaches the physical limit, 3D integration technology has become a new development direction. By stacking multiple chips or wafers vertically, 3D integration technology can significantly improve the performance and functionality of a chip without increasing the chip area. For example, Intel's Foveros technology enables 3D stacking of chips, improving data transfer speed and computing efficiency. This technology is not only used in the field of high-performance computing, but also shows great potential in devices such as smartphones and the Internet of Things.

(三) The trend of heterogeneous integration is increasing

Heterogeneous integration is the integration of different types of chips (such as CPUs, GPUs, FPGAs, etc.) within the same package for greater functionality and higher performance. This trend meets the needs of different application scenarios for the diverse functions of chips. For example, Nvidia has integrated ARM-based CPUs into its GPU chips, enabling computing and graphics processing to work together, providing more powerful support for areas such as artificial intelligence and gaming.

二、Market Landscape: Intensified competition and regional differentiation

(一)The oligopoly pattern has strengthened

In the global wafer foundry market, TSMC, Samsung and other companies dominate with advanced technology and huge production capacity. TSMC's market share has long exceeded 50%, and it is far ahead in the field of advanced processes. Samsung has strong competitiveness in memory chips and foundry business. This oligopoly pattern is difficult to change in the short term, and other companies need to seek breakthroughs in technological innovation and market positioning.

(二)The rise of the Chinese mainland market

In recent years, the semiconductor wafer industry in Chinese mainland has developed rapidly. SMIC, Hua Hong Semiconductor and other enterprises continue to improve their technical level and production capacity. SMIC has strong competitiveness in mature process areas and is actively catching up with advanced process technologies. At the same time, the support of national policies and the investment of a large amount of capital have attracted many talents and enterprises to enter the field, injecting strong impetus into the development of the semiconductor wafer industry in Chinese mainland.

(三)Regionalization, competition and cooperation coexist

With the adjustment of the global semiconductor industry chain, the trend of regional competition and cooperation is obvious. Countries have introduced policies to encourage the development of the local semiconductor industry to ensure the security of the supply chain. For example, the United States passed the CHIPS and Science Act to increase support for the local semiconductor industry; The European Union has also put forward an ambitious plan for the development of semiconductors. At the same time, cooperation between multinational companies is increasing to jointly address technological challenges and market competition.

三、Material Innovation: Diversity and High Performance

(一)Silicon-based materials are continuously optimized

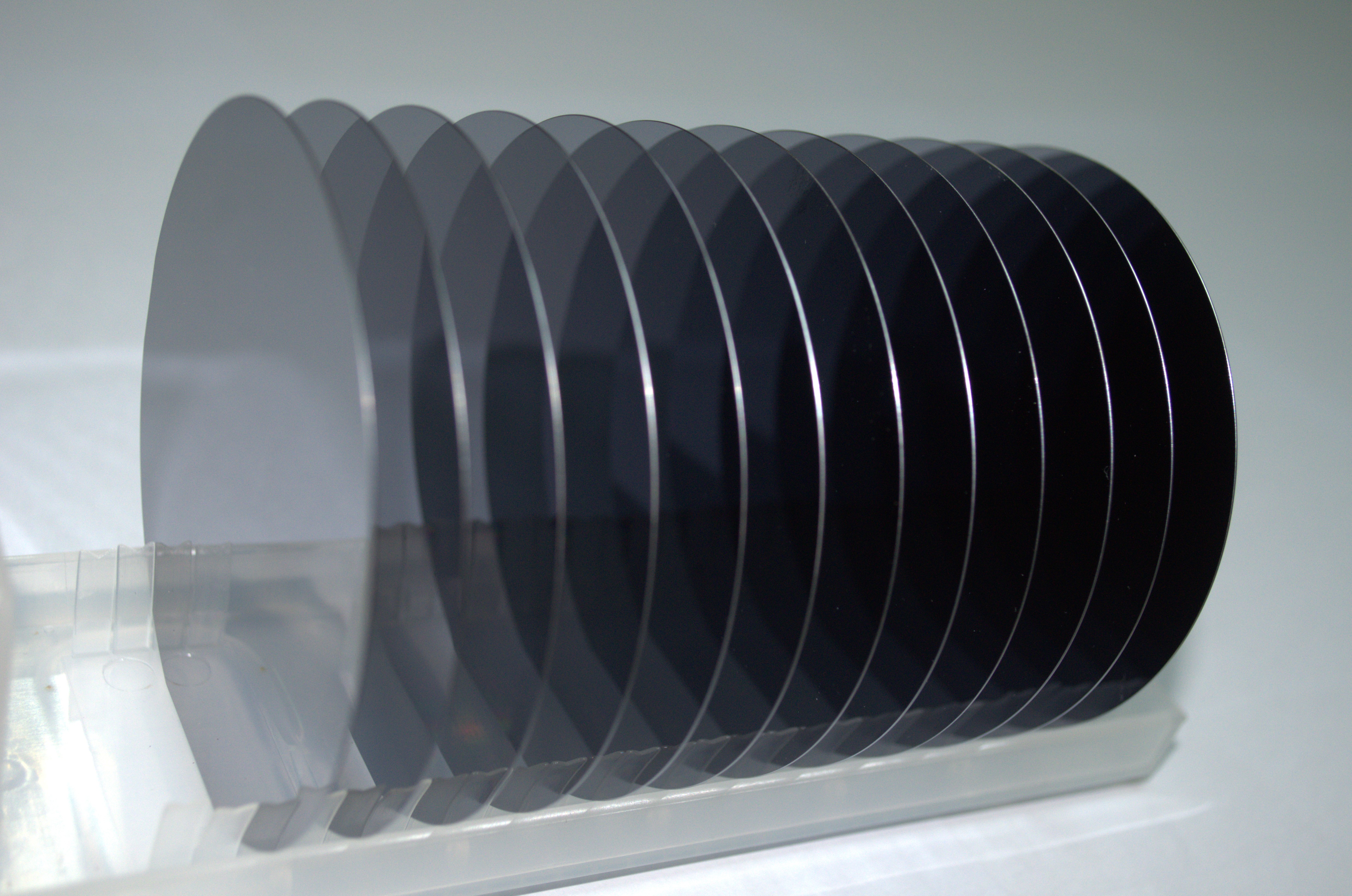

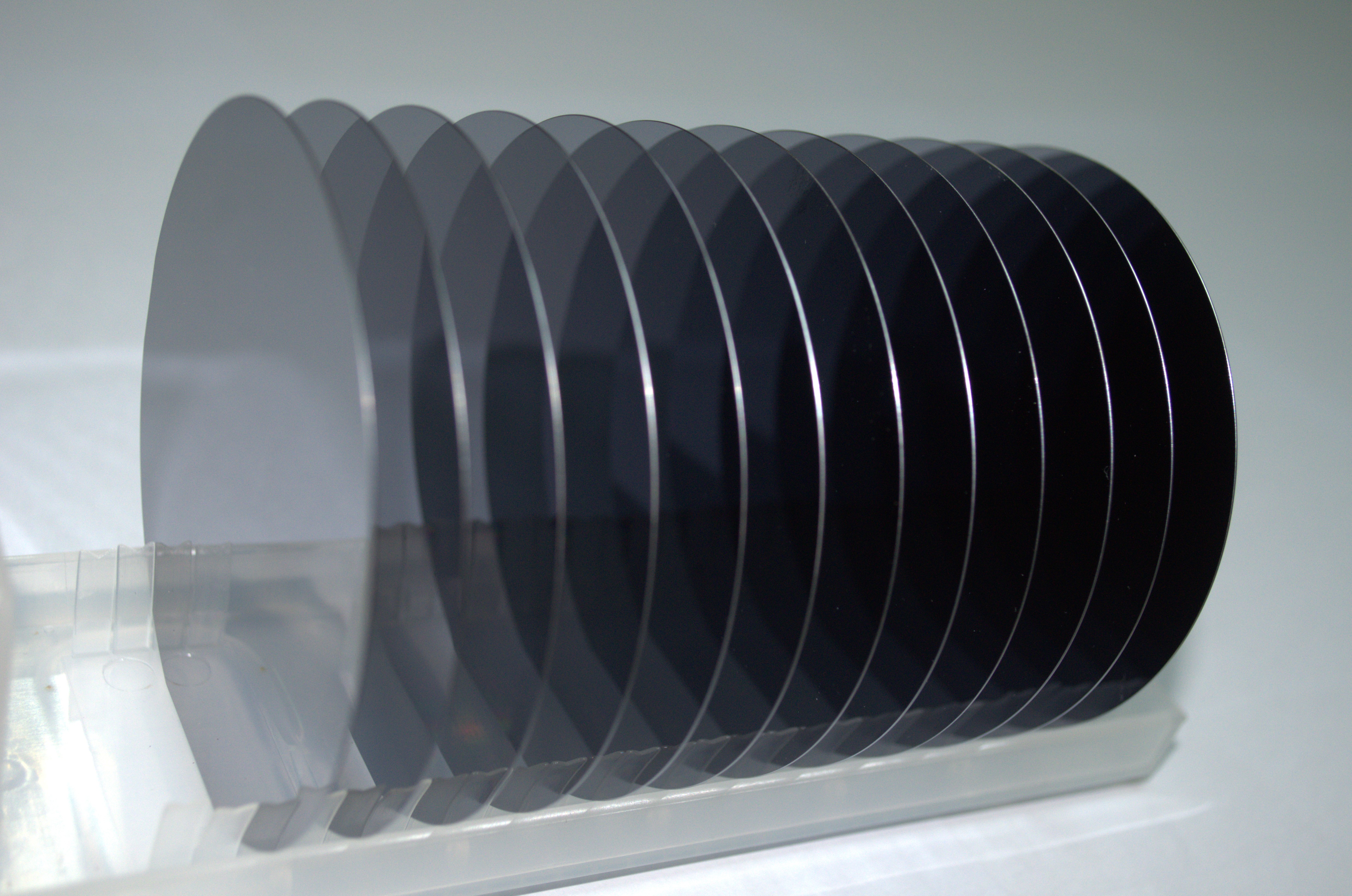

Silicon-based materials are still the mainstream materials for semiconductor wafers, but with the development of technology, the performance requirements for silicon-based materials are getting higher and higher. The performance of silicon-based materials has been further improved by optimizing the crystal structure of silicon wafers and reducing defect density. For example, silicon wafers applied to 12-inch wafers have extremely high levels of flatness and purity, ensuring advanced process technology.

(二)Wide bandgap semiconductor materials are emerging

Wide bandgap semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) have the advantages of high breakdown electric field and high electron mobility, and have shown great advantages in power semiconductors, radio frequency devices and other fields. In the charging pile of new energy vehicles, silicon carbide power devices can improve charging efficiency and reduce energy consumption; GaN RF devices are widely used in 5G communication base stations. The application of these wide bandgap semiconductor materials has promoted the diversified development of semiconductor wafer materials.

(三)New materials are constantly being explored

In addition to silicon-based materials and wide bandgap semiconductor materials, scientists are also constantly exploring new semiconductor materials, such as two-dimensional materials (graphene, molybdenum disulfide, etc.), quantum dot materials, etc. These new materials have unique physical properties and are expected to bring new breakthroughs to the semiconductor industry. For example, graphene has excellent electrical and mechanical properties, and may be used in high-speed transistors and sensors in the future.

四、Industrial ecology: coordinated development and innovation-driven

(一)The synergy and cooperation of the industrial chain have been strengthened

The development of the semiconductor wafer industry is inseparable from the collaboration of upstream and downstream enterprises in the industrial chain. From wafer manufacturing, chip design, foundry to packaging and testing, all links are closely linked. For example, chip design companies work closely with foundries to jointly develop new process technologies and chip products; Equipment manufacturers and material suppliers also need to collaborate to innovate to provide advanced equipment and materials for wafer fabrication. Through the synergy and cooperation of the industrial chain, the efficiency and competitiveness of the overall industry can be improved.

(二)Industry-university-research cooperation deepened

In order to overcome key technical problems, the industry-university-research cooperation in the semiconductor wafer industry has been deepened. Universities and scientific research institutions play an important role in basic research and cutting-edge technology research and development, providing theoretical support and technical reserves for industrial development. Enterprises cooperate with universities and scientific research institutions to transform scientific research results into actual productivity. For example, Tsinghua University has cooperated with a number of semiconductor companies and achieved a series of important achievements in the fields of integrated circuit design and manufacturing.

(三)Innovation ecosystem building

In order to create a favorable innovation environment, semiconductor wafer innovation ecosystems have been built in various places. Through the construction of industrial parks, incubators, accelerators and other innovation carriers, we will attract innovative enterprises and talents. At the same time, the government has also introduced a series of policies and measures to encourage enterprises to increase R&D investment and carry out technological innovation. For example, the Zhangjiang Hi-Tech Park in Shanghai has brought together many semiconductor companies and scientific research institutions, forming a complete innovation ecosystem and promoting the rapid development of the semiconductor wafer industry.

As the core of the semiconductor industry, the development trend of semiconductor wafers affects the direction of the entire industry. Driven by technological innovation, market competition, material transformation and industrial ecological reconstruction, the semiconductor wafer industry will usher in a more brilliant stage of development, providing strong technical support for the global digitalization process.